Concrete Flatwork Installation in South Jordan

Concrete Flatwork South Jordan

Concrete flatwork installation is an excellent way to create a functional and durable surface on your South Jordan property. Whether you are looking at installing a driveway, patio, walkway, or pool deck, professional concrete flatwork installation will ensure that your new surface has been installed with all of the necessary steps in place to provide years of durability in the Utah climate. Knowing how your contractor plans to install your concrete flatwork will help you decide which contractor to hire, when they will complete your job, and what you can expect from your contractor during this time. All of these steps require a certain amount of knowledge, skill, and experience, as well as quality equipment to produce a long-lasting product that adds value to your home and enhances its curb appeal. Proper installation of your concrete flatwork will also prevent many problems, such as cracks, settlement, and early deterioration.

Initial Planning and Site Evaluation

Contractors first evaluate your site to determine soil type, drainage pattern, and access. Contractors also locate underground utilities to avoid damaging them during excavation. Contractors establish property boundaries and setbacks to ensure you comply with the South Jordan Zoning Ordinance and Building Codes. Contractors will also discuss design criteria, which can include your desired use, traffic flow, aesthetics, etc., as it will help dictate thickness, reinforcing steel, and finish specs for your new concrete. Concrete contractors in Utah must consider Utah’s freeze-thaw cycle, which affects how they design their mixes and plan their installs.

Regulatory Compliance and Permit Requirements

Depending on the size, location, and structural requirements, South Jordan has some building code requirements for concrete flatwork (driveways, sidewalks, patios) requiring a building permit. Depending on the modification to your driveway, you may need to obtain approval from the Engineering Department if it is in a public right-of-way. Contractors will complete the permitting process and be responsible for ensuring all applicable building codes are met during the installation process. Commercial projects or publicly accessible areas in residential developments may have ADA Accessibility requirements. Contractors will properly calculate the slope and texture of your finished product to ensure compliance with safety standards and provide proper drainage.

Excavation and Site Preparation

After completing the permitting process and ensuring compliance with all building codes, Contractors will begin excavating your site. The first step in this process is to mark out your job boundaries with either spray paint or stakes, as per the approved plans. Based on your site conditions, job size, and access within your neighborhood, Contractors will select the best equipment for your project. Contractors will then excavate to the correct depth to accommodate your sub-base material, concrete thickness, and final elevation requirements. After removing the dirt from your site, Contractors will dispose of it according to environmental regulations while attempting to minimize disruption to any landscaping or hardscaping around your site. Contractors will take the required steps to protect any utilities located beneath your site, including irrigation systems, electrical lines, and gas lines. If necessary, Contractors will contact the respective utility companies to ensure a safe excavation process.

Preparation of Sub-Base Material and Compaction

The quality of your sub-base materials is what will ultimately determine whether your concrete will settle and crack over time. Using granular materials such as crushed rock or recycled concrete aggregate will allow for proper drainage and will adequately support the structural loads on your slab. Contractors will properly grade the materials to ensure adequate compaction and load distribution throughout the project area. Contractors will then use the proper compaction equipment to achieve the required density as specified in the engineered plans, using either a plate compactor or vibratory roller. Contractors will also optimize the moisture content of the sub-base material before compaction to prevent any future settlement issues that could affect the integrity of your concrete flatwork. Upon completion of the compaction process, Contractors will perform the required testing to confirm that the sub-base material has achieved the density as specified in the engineered plans before proceeding with placing the concrete.

Placement of Forms and Rebar

Concrete forms are used to define the edges of your concrete and control the final elevation of your concrete. Contractors will use high-quality materials for the forms and ensure they will hold up against the concrete pressure while maintaining a straight line and proper grade. Contractors will properly secure the forms and install the required stakes to prevent movement of the forms during the placement of the concrete and the finishing of the concrete. Contractors will install the required rebar for your project, based on the engineer’s designs and load requirements, as well as the required spacing, positioning, and concrete cover for the rebar. During the placement of the concrete, Contractors will use chair supports to maintain the position of the rebar and protect the rebar from moisture and corrosion.

Planning of Drainage and Joints

Designing proper drainage will eliminate water from accumulating under your concrete that would cause freeze-thaw damage during Utah’s winters. Contractors will design the surface to direct the water away from your structures while providing functional accessibility and aesthetics. Contractors will also design the drainage system to work with your existing landscape features and prevent erosion and damage to your structure’s foundation. Contractors will strategically place control joints to prevent random cracking of your concrete by providing predetermined locations for your concrete to move. Contractors will calculate the spacing of the joints based on the thickness of your concrete, the size of your aggregate, and the environmental conditions specific to your location in South Jordan, UT. Contractors will properly install the joints and apply the required sealants to maintain weather protection for years to come.

Concrete Mix Design and Delivery

Contractors will select the concrete mix design that will meet your strength requirements, workability needs, and environmental exposure conditions found throughout the Salt Lake Valley. Contractors will add air-entraining agents to the mix to protect your concrete from freeze-thaw damage while still allowing for proper workability for the placement and finishing of your concrete. Contractors will source their aggregates from local Utah suppliers to provide the most cost-effective solution possible that meets their performance specifications. Contractors will schedule the delivery of your ready-mix concrete to coordinate with the weather conditions, their crews’ availability, and your project’s timeline. Contractors will coordinate with the ready-mix truck drivers to navigate the roads in South Jordan, while being aware of any weight restrictions and access limitations within your neighborhood. Contractors will time the delivery of your concrete to ensure placement begins as soon as possible after delivery to maintain its workability and prevent cold joints.

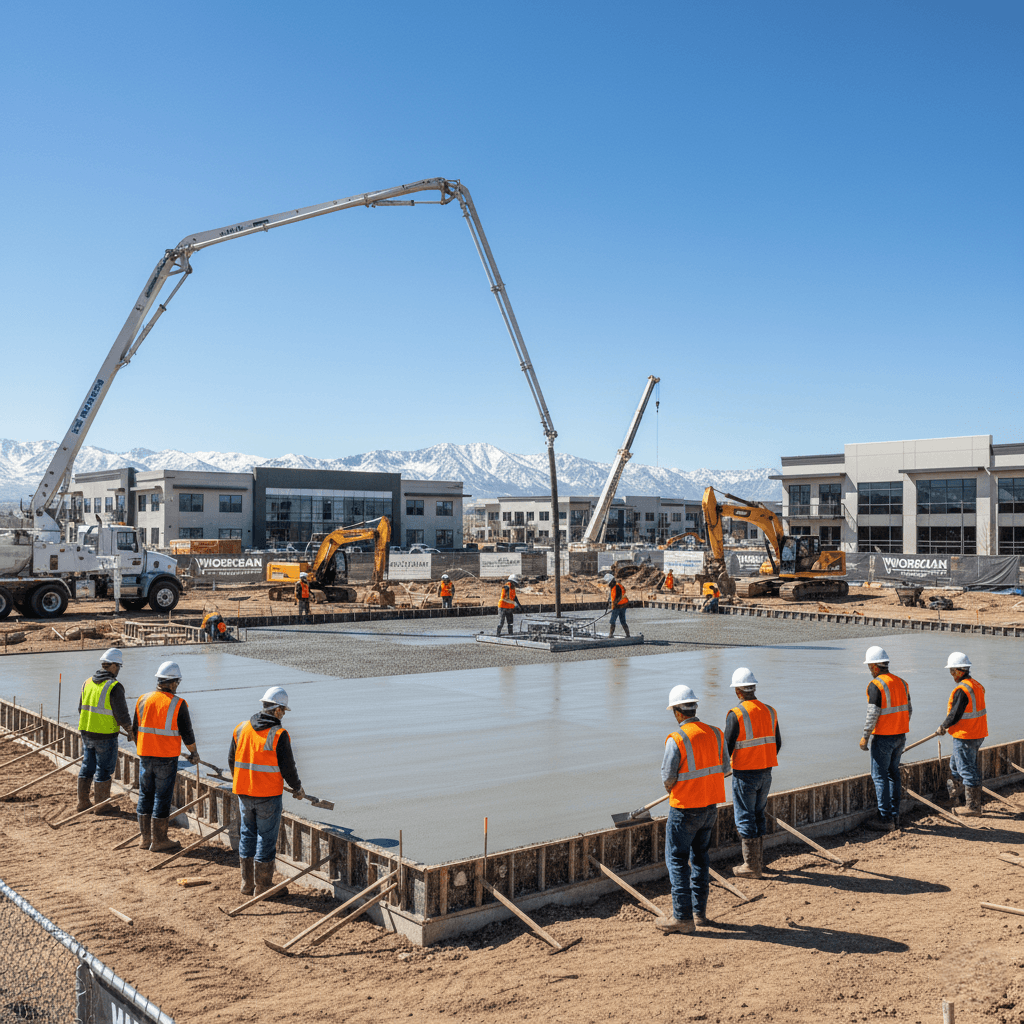

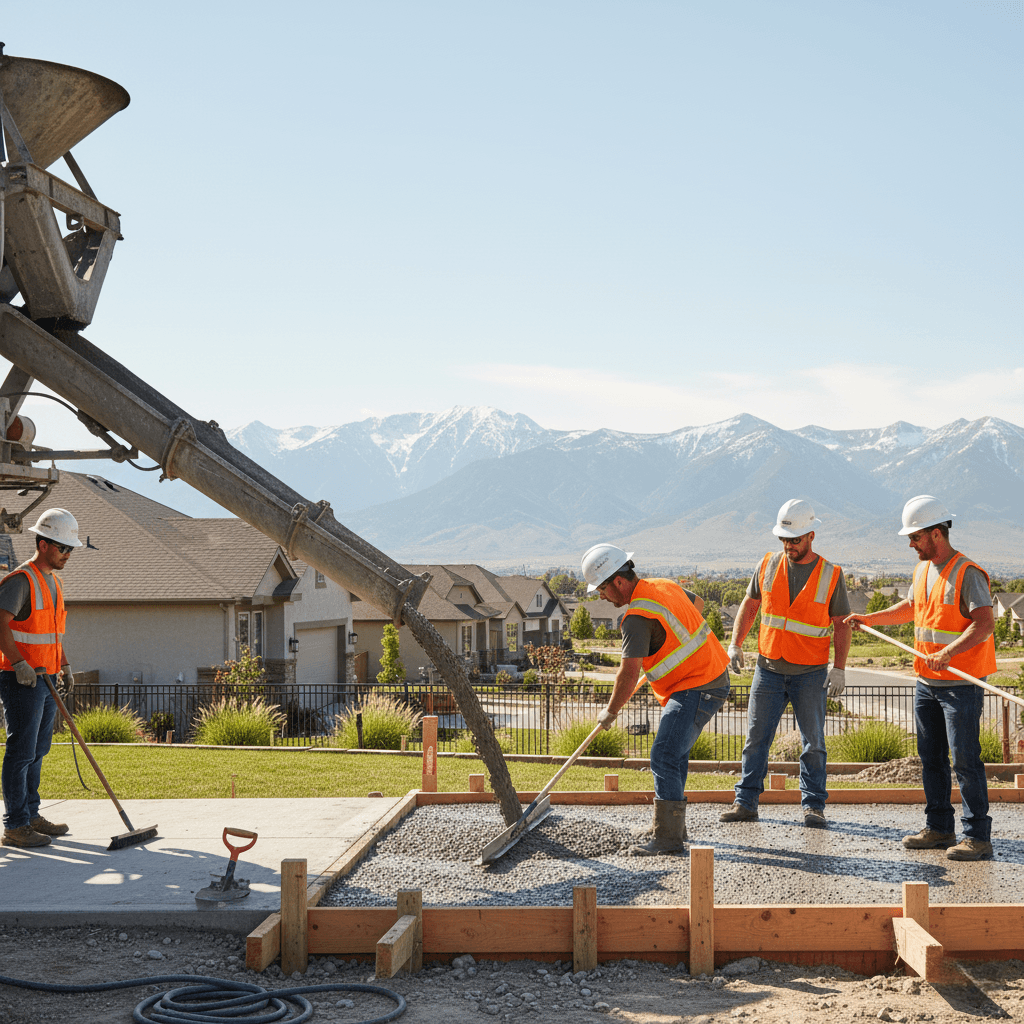

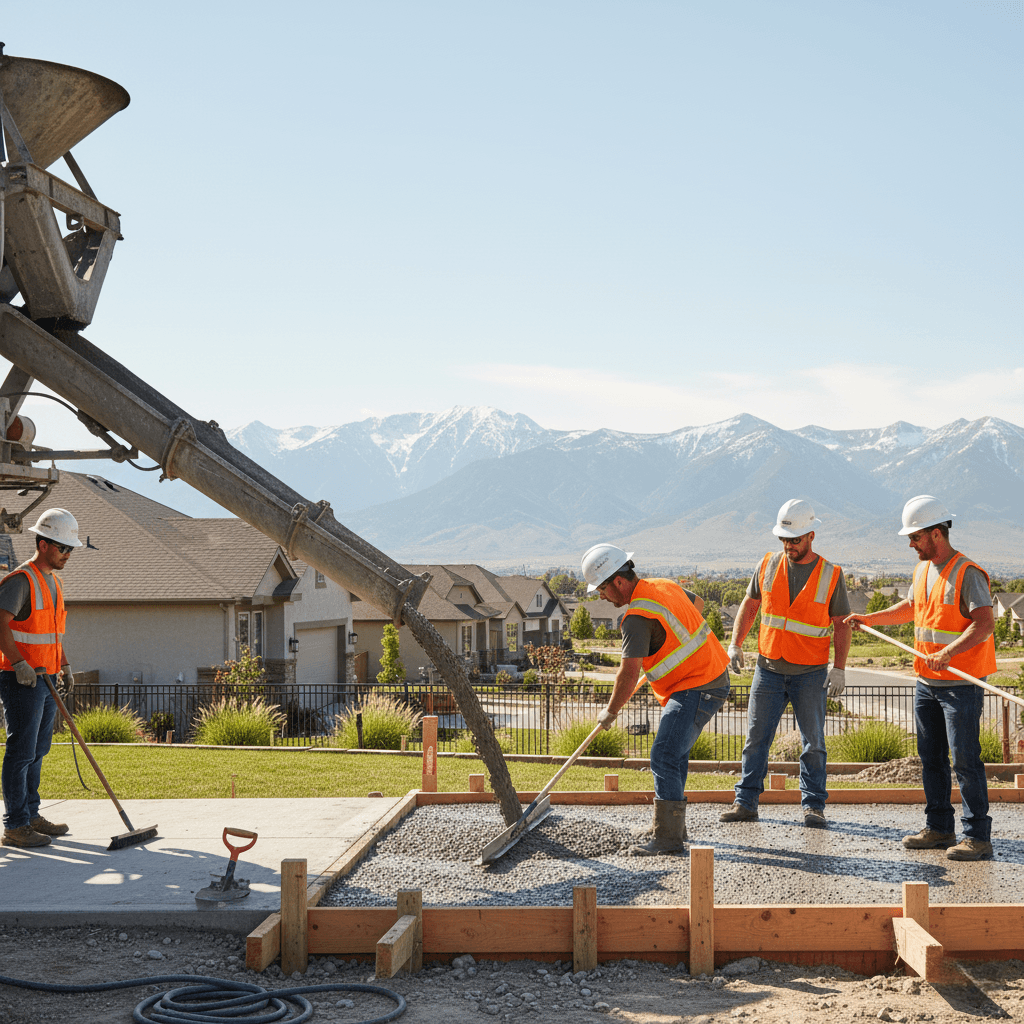

Placing Concrete

Contractors will systematically place your concrete starting at one end and working their way across the entire project area to prevent cold joints and to ensure even consolidation. Contractors will use pumps to place the concrete where access is limited or where the distance from the mixer truck to the placement location is too great for a boom truck. Contractors will use vibrators to consolidate the concrete while avoiding over-vibrating the concrete, which could cause segregation. Contractors will use screed boards to level your concrete surface to the required elevations, using a straight edge tool guided by your forms or grade stakes. Contractors will make multiple passes with the screeds to ensure that your concrete surface is uniform in thickness and smoothness throughout the entire project area. Contractors will use the proper techniques to maintain the proper consistency of the concrete throughout the placement process.

Finishing the Surface and Texture

Contractors will remove the surface irregularities from your concrete surface with a float while introducing cream to the surface for proper troweling operations. Contractors will carefully consider the timing of each finishing operation to ensure the workability of the concrete is maintained while coordinating with the weather conditions and the set characteristics of the concrete. Experienced finishers understand the optimal timing for each finishing operation to produce the specified surface quality. Contractors will apply textures to your concrete surface to provide sufficient slip resistance for safety while maintaining aesthetic appeal. Contractors will use broom finishes to provide excellent traction for your driveways and walkways that will be subject to Utah’s winter weather conditions. Contractors will utilize specialized texturing tools to create decorative patterns that will enhance the visual appeal of your concrete while not compromising functionality.

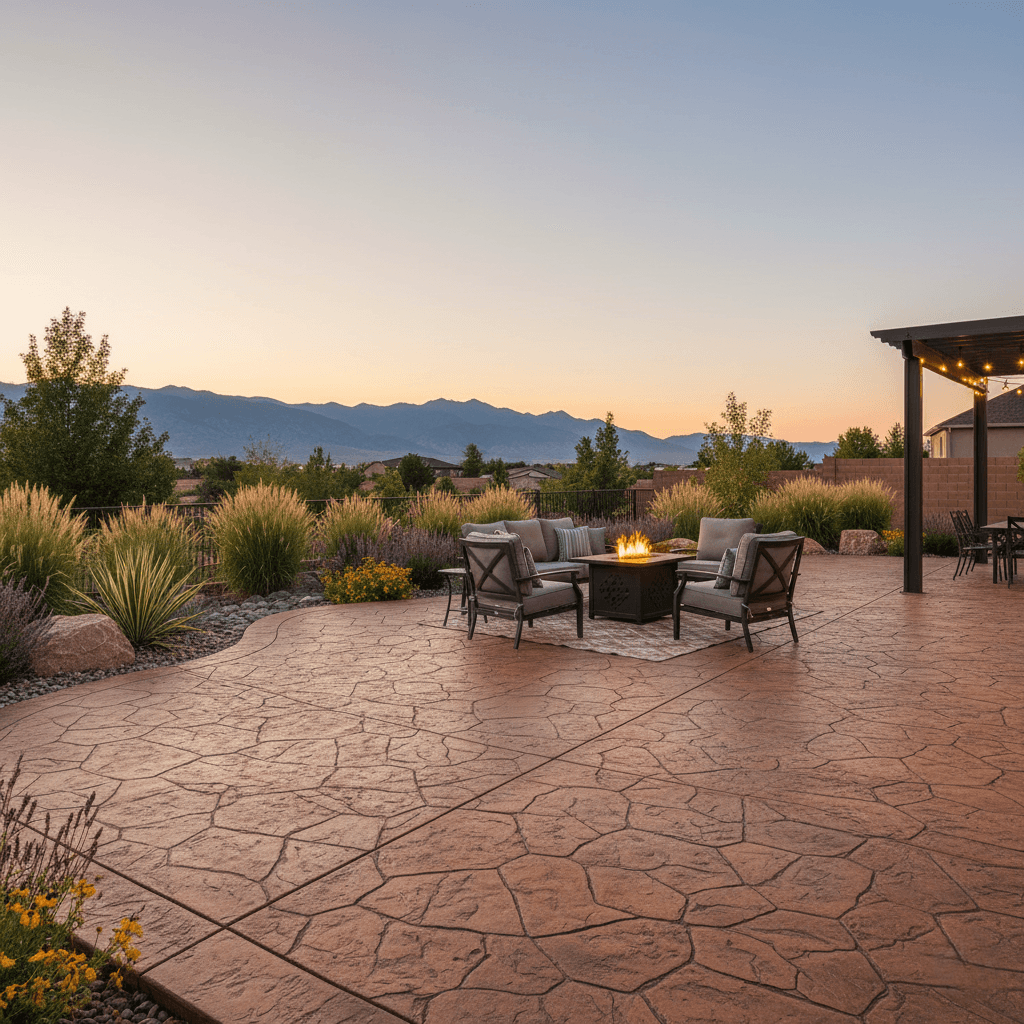

Decorative Finishing Options

Stamped concrete provides attractive patterns that simulate expensive materials such as natural stone, brick, or wood at a fraction of the cost of replacing them. Contractors will integrate color into your stamped concrete using either integral pigments or surface treatments to enhance the visual appeal of your concrete while maintaining durability. Contractors will apply the same high-quality techniques consistently throughout your project to ensure that your stamped concrete complements your property’s architecture and landscaping. Contractors will expose decorative stones within the concrete mix to create an exposed aggregate finish with a unique textural appeal. Contractors will control the depth of exposure while maintaining surface durability and slip resistance using specialized techniques. Contractors will produce a uniform finish that will last for years to come in Utah’s harsh environment and typical wear patterns.

Protective Measures During Curing

Contractors will maintain the required moisture and temperature conditions for your concrete to develop the maximum strength and durability possible. Contractors will apply a curing compound or wet covering to protect your surface from excessive moisture loss during the critical early strength development period. Due to Utah’s dry climate, contractors must pay particular attention to maintaining the required moisture retention during the curing process. Contractors will take protective measures to prevent freeze damage during cold-weather construction and avoid excessive moisture loss during warm-weather construction. Contractors will use insulating blankets or heated enclosures to maintain the proper curing temperatures when weather conditions present a threat to the quality of your concrete. Contractors will monitor the curing process to ensure that the required curing conditions are maintained during the critical strength development period.

Weather Conditions and Project Scheduling

Contractors will consider the seasonal weather patterns in South Jordan when scheduling your project. Most concrete flatwork projects will occur during spring and fall. Contractors will take special precautions during the summer heat and will take additional protective measures during winter construction. Contractors will extend the curing periods to ensure that your concrete develops the proper strength before allowing traffic and normal use. Contractors will schedule your project to ensure that all of the required trades and activities are completed promptly while maintaining quality standards throughout the installation process. Contractors will establish realistic timelines that account for weather-related delays and the required curing times.

Final Inspection and Quality Control

Contractors will provide quality control for your project by testing the concrete, monitoring the placement of the concrete, and verifying the finishing of the concrete throughout the installation process. Contractors will test the slump of your concrete to ensure it meets the required consistency. Contractors will measure the air-content in your concrete to ensure it contains enough air-entraining agents to protect the concrete from freeze-thaw damage. Contractors will test the compressive strength of your concrete to ensure it meets the required strength specifications for long-term performance. Contractors will conduct a final inspection of your project to verify the surface quality, joint placement, and overall workmanship before accepting your project. Contractors will document the results of the testing performed, the certification of the materials used, and the records of the installation of your concrete to provide warranty protection. Contractors will implement quality assurance programs to identify and rectify any deficiencies before completing your project.

Ongoing Maintenance and Care

Once your concrete cures completely, you may allow light foot traffic on it; however, you should continue to protect your concrete from heavy loads and vehicle use until it reaches full strength. Contractors will recommend the application of a sealer to your decorative finishes to protect them from stains and maintain their appearance for years to come. Contractors will guide you in establishing a regular maintenance schedule and provide recommendations for caring for your concrete. Contractors will consider the seasonal maintenance needs of your concrete, including protecting the surface from damage caused by improper snow removal methods. Contractors will recommend sealing the joints to prevent moisture from entering the joint and causing freeze-thaw damage that could weaken the structural integrity of your concrete. Contractors will establish ongoing maintenance programs to extend the service life of your concrete while maintaining its aesthetic appeal and functionality. South Jordan Concrete Pros manages every aspect of your concrete flatwork project from the initial planning stages through the completion of your project, ensuring that we deliver a professional result that will enhance your property for years to come. Our comprehensive approach includes preparing the site correctly, using quality materials, installing your concrete professionally, and providing ongoing support to ensure that your concrete performs optimally in Utah’s extreme climate conditions.