Commercial Concrete Projects in South Jordan

Commercial Concrete South Jordan

Commercial concrete projects in South Jordan are successful because of a combination of proper planning, local code compliance, and experienced professionals who manage all aspects of the project. The most effective way to avoid time-consuming delays is to understand local building codes, permits required, and requirements from contractors. Choosing the correct materials, designing the structure correctly, and creating a realistic construction schedule will increase the performance of the finished product while staying within your budget. Compliance with the Americans with Disabilities Act (ADA) and Accessibility Standards is extremely important when designing public and commercial facilities. Effective Project Management is essential to coordinate all the trade work, inspections, and Quality Control/Quality Assurance during the construction process.

Building Code Compliance and Permits

South Jordan adheres to the 2021 International Building Code for commercial construction projects. This will help assure the structural integrity and performance standards for your project. Any new construction, addition, or major renovation of a commercial project that exceeds certain dollar values will require a building permit. Contractors who wish to perform work on a commercial project must be properly licensed by the State of Utah and obtain the required permits. The application process for building permits includes submitting detailed drawings and plans for the construction project, which will be reviewed by the building, fire, engineering, and community development departments before you start construction. Once your project is complete, the City of South Jordan will conduct a Certificate of Occupancy inspection to ensure that your project complies with all applicable codes and that your business is ready to operate.

Contractor Licenses and Insurance Requirements

The Utah Division of Occupational and Professional Licensing (DOPL) has established contractor classification requirements for performing commercial concrete work. A B100 license is required of General Contractors working on commercial buildings, and an S260 License is required of Specialty Contractors who install asphalt and concrete. In addition to a contractor’s license, DOPL requires that each contractorcarrys at least $100,000 worth of general liability insurance to cover one incident and no less than $300,000 worth of general liability insurance to cover one year. Workers’ Compensation Insurance is also required of any contractor who employs anyone. This provides liability protection to the employee and the property owner in the event of an accident. Surety Bonds provide further protection to the client and government agencies of the contractor’s reliability. The contractor’s licenses, insurance, and surety bonds assure that the contractor has sufficient knowledge and experience to complete the job and comply with all applicable laws and regulations.

ADA Accessible and Universal Design Requirements

All commercial facilities must be compliant with the Americans with Disabilities Act (ADA). The ADA requires that all commercial facilities have accessible entrance/exit points, ramps, hallways, doorways, and restrooms. The ADA also requires that the surface of the concrete and other flooring must allow for easy movement of wheelchairs and other mobility devices. There must be designated parking spaces that meet the ADA requirements for size and slope of the parking area. In addition to the ADA requirements, universal design requirements should be followed to create a functional environment that can be used by everyone regardless of age, ability, or disability. For example, tactile warnings, adequate lighting, and way-finding signs are important features to consider when designing an environment for people with visual impairments. It is recommended that you hire a professional to consult with you regarding accessibility and universal design requirements so that you can create a safe and functional environment for everyone.

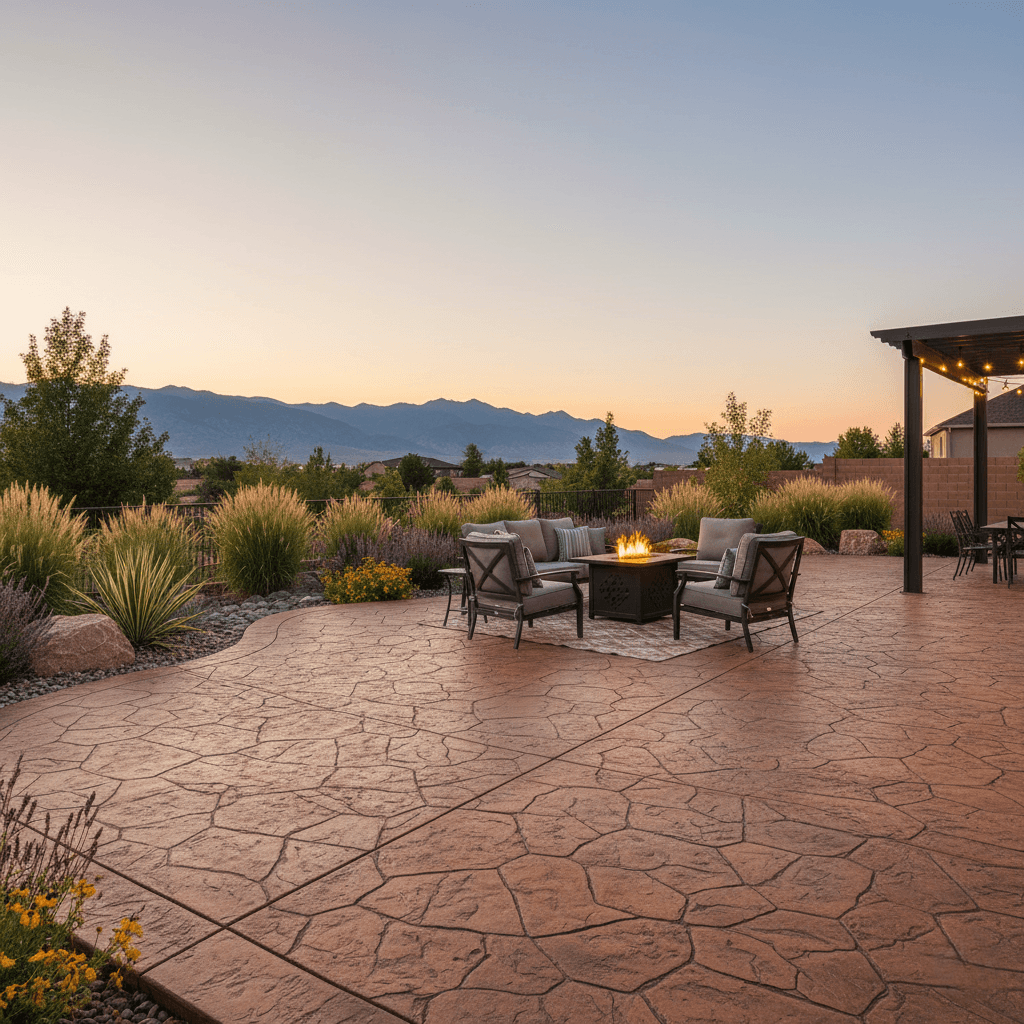

Slip Resistance and Safety Requirements

Concrete surfaces in commercial properties must have sufficient slip resistance to prevent slipping and falling hazards. Slip-resistant finishes can be applied to the outside of commercial properties where there is a possibility of water on the concrete surface due to rain, snow, or irrigation systems. Inside commercial properties, it is essential to balance slip resistance with the aesthetic appeal and maintenance requirements of the surface. Loading docks and industrial facilities require specialized surface treatments that provide high slip resistance and can support heavy equipment loads. Emergency exit paths must also meet specific slip resistance requirements and must be clearly marked as emergency exits. When selecting the correct surface finish for your commercial property, it is highly recommended that you select a finish that is specifically designed to meet the safety requirements of your property.

Engineering and Load Calculations

Commercial concrete projects require professional engineering to ensure that the structural system can support the expected loads and that the structure is safe and durable. Loads that engineers must calculate include live loads (people walking on the floor), dead loads (weight of the roof, walls, floors, etc.), seismic forces (earthquake forces), and environmental factors such as wind and snow. Utah’s Seismic Zone Classifications require that structures be designed to resist earthquakes and, therefore, must be analyzed for seismic loads. Geotechnical reports and soil analysis must be performed to determine the type and amount of footing required for the building and to determine if the soil can support the weight of the building. If the soil cannot support the weight of the building, the engineer must recommend deep foundations, soil stabilization, or specialized construction techniques. By hiring a professional engineer, you can be assured that your building will be structurally adequate and that materials will be used efficiently and effectively.

Weather and Frost Protection

South Jordan has a minimum frost depth of 30 inches, which must be considered when designing the foundation of a commercial building. During Utah’s winters, freeze-thaw cycles can cause damage to the concrete and, therefore, must be taken into consideration when selecting the concrete mix and curing procedures. Air entrainment and selecting the right aggregates can help to protect the concrete from the effects of freezing and thawing. In the summer, the heat and dryness can cause rapid drying of the concrete and damage to the finished product. Therefore, it is essential to use the right curing techniques, such as keeping the concrete moist and controlling the temperature of the concrete during the curing period, to achieve maximum strength and durability. When constructing a commercial building, it is essential to consider the weather conditions and how they will affect the concrete.

Concrete Mix Design and Materials

When designing a high-performance concrete mix for a commercial application, it is essential to consider the strength, durability, and workability requirements of the mix. The compressive strength of commercial concrete can vary from 3,000 PSI to 6,000 PSI, depending on the structural requirements and the expected loads on the building. Admixtures can be added to the mix to increase its workability, reduce shrinkage, and improve its overall durability. The choice of aggregate can also affect the performance of the concrete, and local sources of aggregate can provide cost-effective solutions that meet quality standards. Additional cementitious materials such as fly ash and silica fume can also be added to the mix to improve the durability of the concrete and possibly reduce the environmental impact of the project. When designing a high-performance concrete mix for a commercial application, it is essential to consider the above factors and to hire a professional to assist in the mix design process.

Testing Procedures and Quality Assurance Programs

Commercial projects require comprehensive quality assurance programs, including material testing, batch monitoring, and field verification procedures. Compressive strength testing at predetermined times during the construction process ensures that the concrete being placed is meeting the design requirements of the project. Slump tests and air content measurements verify the workability of the mix and whether the mix was placed correctly. Independent third-party testing services provide objective evidence of the quality of the concrete and whether the project specifications are being met. Record-keeping requirements include documentation of test results, batch tickets, and placement records to provide warranty and liability protection. Professional quality assurance programs minimize defects and ensure long-term performance and regulatory compliance.

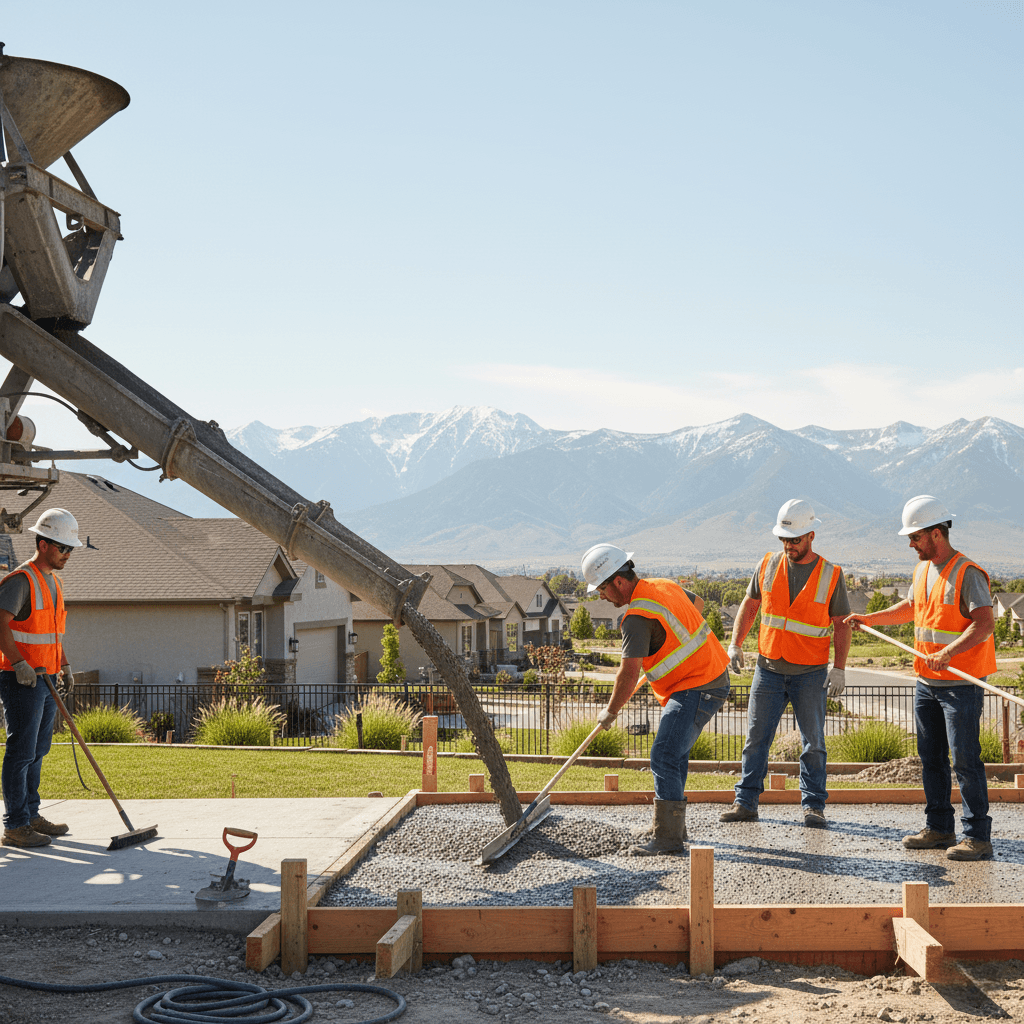

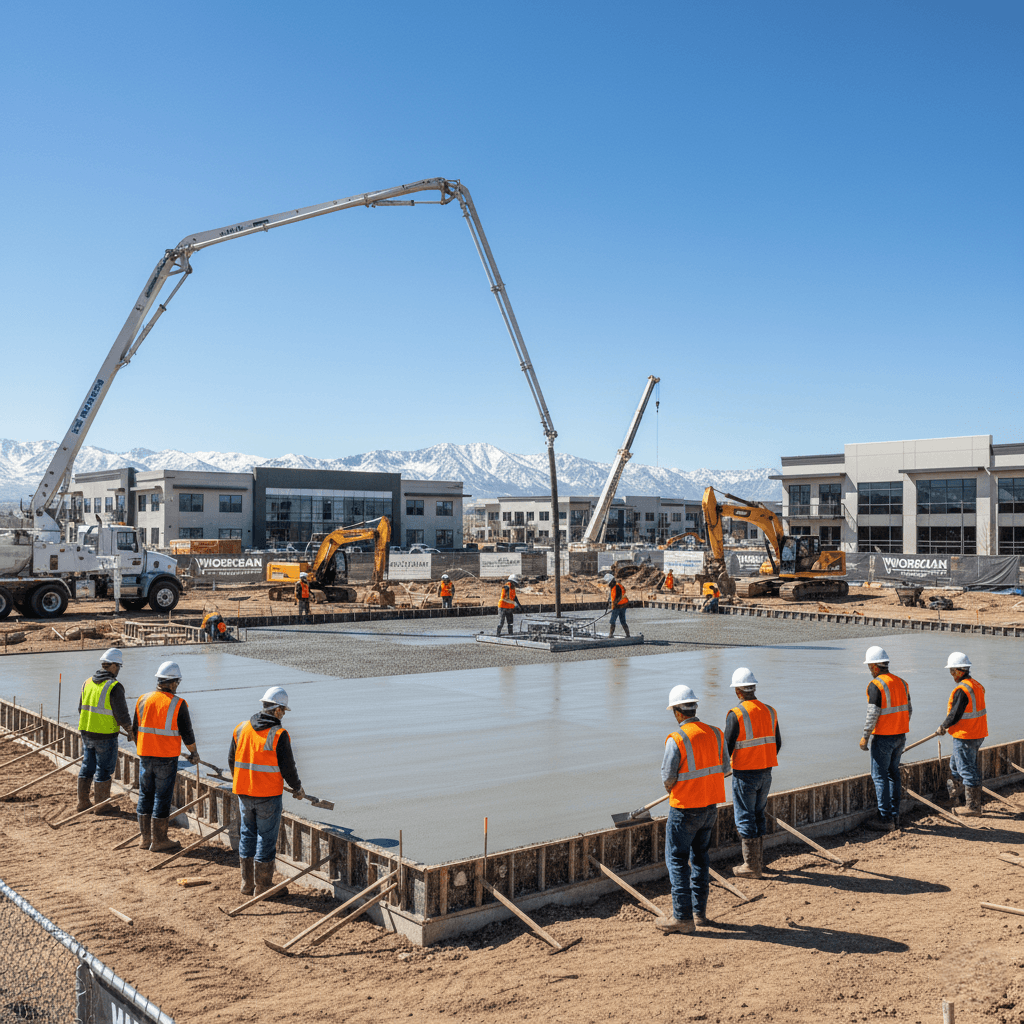

Scheduling and Logistics

Commercial concrete projects require a well-coordinated and detailed construction schedule that takes into account concrete pouring, the curing period, and the subsequent construction activities. When constructing multi-story buildings, sequential pours are typically required with specific timing requirements to ensure that the structural members are continuous. Weather contingencies and seasonal considerations can affect scheduling and material choices. The location of the construction site must also be taken into account when determining the logistics of the project. In urban areas, such as South Jordan, the contractor must plan for adequate space for concrete trucks, pumping equipment, and materials storage areas. Additionally, the contractor may need to obtain special permits for street closures or oversized equipment access. Professional project managers coordinate the trades, inspections, and material deliveries to ensure the timely completion of the project.

Inspections and Regulatory Compliance

During the construction phase of a commercial project, various building department inspections take place at predetermined milestones. These inspections verify that the concrete has been reinforced correctly, that the mix design is compliant with the project specifications, and that the concrete has cured properly. Professional scheduling ensures that the inspectors have adequate access to the site and prior notice for the required inspections. Documented record-keeping is also required to verify compliance with approved plans, inspection reports, and material certification records. Any changes to approved plans must go through a formal amendment process and receive approval before implementation. Professional project managers ensure that regulatory compliance is maintained and that project delays and disputes are minimized.

Costs and Budget Planning

Commercial concrete projects involve significant expenditures for materials, labor, and equipment that must be carefully planned and controlled. Market fluctuations can affect material costs, and thus contingency planning and potential value-engineering alternatives must be considered. Professional cost estimating considers all aspects of the project from design to completion. Labor costs reflect the level of skill and expertise of the workforce and the local prevailing wages for commercial construction projects. Costs associated with equipment include concrete pumping, finishing tools, and specialized construction equipment. Professional project managers track costs throughout the project to maintain budget compliance and maximize profits.

Value Engineering and Cost Savings

Value engineering is the process of identifying ways to reduce costs while still maintaining the quality and performance of a project. Alternative materials, construction methods, or design changes may be identified to reduce project costs without compromising project goals. Professional evaluation is used to assess alternative options based upon the cost of implementing the option, ongoing maintenance and repair costs, and the overall performance of the option. Construction phasing may also be used to stretch out the cost of completing the project over time while allowing for early occupancy of completed areas. Professional scheduling is used to optimize the use of resources and minimize holding costs during extended construction periods. Strategic planning is used to balance cost control with project schedule requirements and quality objectives.

Maintenance and Repair Planning

Commercial concrete projects must be properly maintained to extend the useful life of the concrete and minimize repair costs and interruptions to normal operation. Preventive-maintenance schedules must be developed to address the typical uses and exposures of the building and the expected performance requirements of the building. Professional maintenance programs must include inspection schedules, cleaning procedures, and repair protocols. Warranty considerations must include the performance of materials, workmanship quality, and maintenance requirements that may affect the duration of warranties. Professional documentation must be maintained to support warranty claims and to show that the building has been properly maintained. Professional planners should develop long-range plans for replacing components of the building and upgrading the building to maintain its performance and appearance over time. South Jordan Concrete Pros specializes in commercial concrete projects that meet all regulatory requirements and provide excellent quality and value. We have the experience and staff to manage every step of a commercial concrete project from the planning stage through project completion and ensure that our clients are satisfied with the outcome of their project.