Concrete Pouring Do’s and Don’ts in South Jordan

Pouring Concrete South Jordan

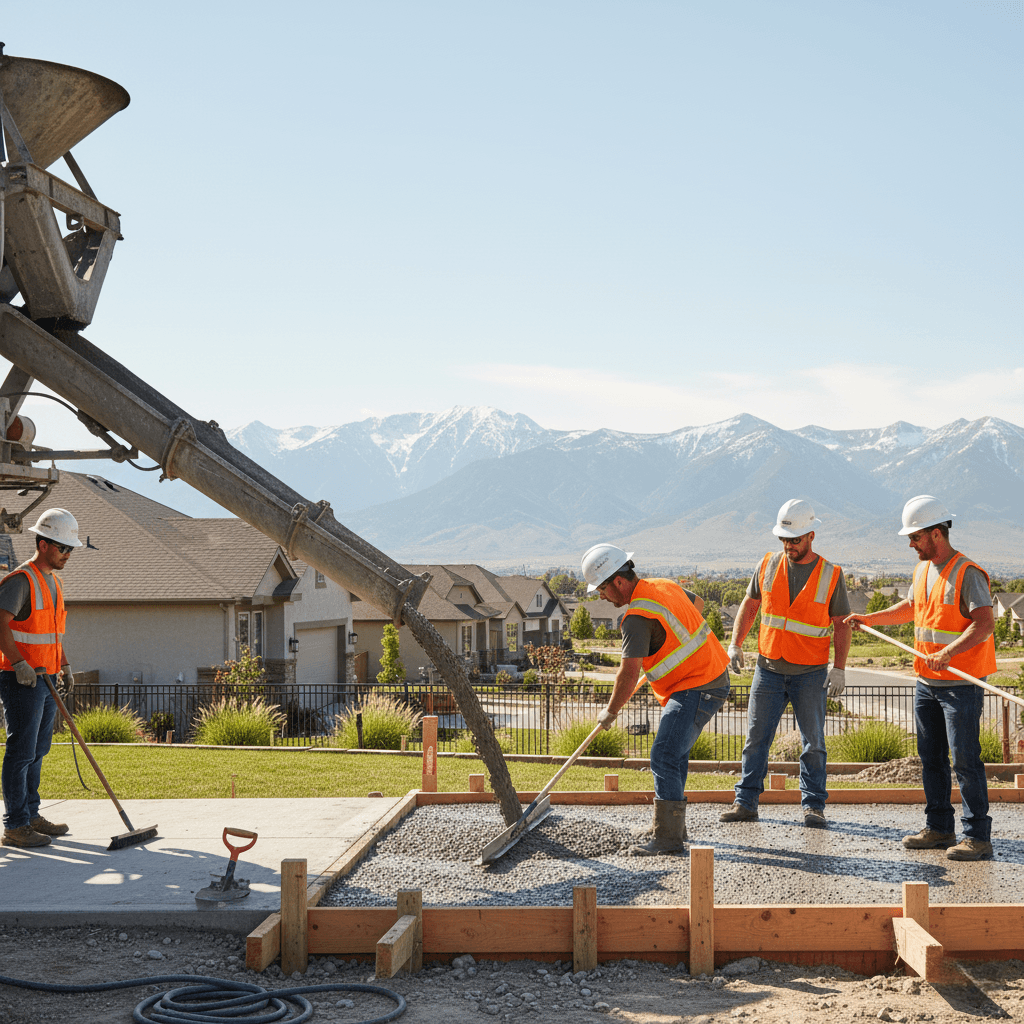

Successfully pouring concrete in South Jordan requires understanding common installation mistakes that can compromise structural integrity and long-term performance. Utah’s unique climate conditions, including extreme temperature variations and challenging soil types, demand specific techniques that many inexperienced installers overlook. Professional concrete contractors recognize these potential pitfalls and implement proven strategies to ensure optimal results every time. Moreover, avoiding these mistakes prevents costly repairs and premature concrete failure that can significantly impact property values. Understanding these critical errors helps homeowners make informed decisions about professional installation versus DIY attempts.

Weather and Temperature Do’s and Don’ts

DO monitor weather conditions carefully and plan concrete pours during optimal temperature ranges between 50°F and 80°F when possible. Professional contractors in South Jordan schedule pours to avoid extreme weather while having contingency plans for unexpected temperature changes. DO use appropriate concrete additives, including retarders for hot weather and accelerators for cooler conditions, to maintain proper curing rates.

DON’T pour concrete when temperatures exceed 90°F or drop below 40°F without taking special precautions. DON’T ignore weather forecasts that predict rain, snow, or freezing temperatures within 48 hours of placement. These conditions can severely compromise concrete strength and durability, leading to premature failure and costly repairs.

Seasonal Considerations

DO schedule major concrete projects during South Jordan’s optimal spring and fall seasons when temperature fluctuations are minimal. DO have insulation blankets and protective coverings available for unexpected weather changes. DON’T rush concrete pours to meet deadlines if weather conditions are unsuitable, as proper curing is essential for long-term performance.

Site Preparation Do’s and Don’ts

DO excavate to the proper depth and ensure adequate drainage away from concrete installations. South Jordan’s clay soils require special attention to moisture management and proper compaction techniques. DO install a minimum 4-inch compacted gravel base unless soil conditions are exceptionally stable and well-draining.

DON’T pour concrete directly on loose soil, frozen ground, or areas with standing water. DON’T skip soil testing and preparation steps, particularly in areas with known expansive clay conditions. These shortcuts often result in settlement, cracking, and structural problems that require expensive repairs or complete replacement.

Concrete Mix Do’s and Don’ts

DO select appropriate concrete strength ratings based on intended use, typically 2,500-4,000 PSI for residential applications in South Jordan. DO specify air-entrained concrete for exterior installations subject to freeze-thaw cycles common throughout Utah winters. DO work with local suppliers familiar with regional conditions and proven mix designs.

DON’T use generic concrete mixes without considering local climate requirements and specific project needs. DON’T add excessive water to improve workability, as this significantly reduces concrete strength and increases cracking potential. The water-to-cement ratio directly affects final strength and durability characteristics.

Quality Control Measures

DO request concrete delivery tickets showing exact mix proportions and ensure concrete arrives within one hour of batching. DO perform slump tests to verify proper consistency, maintaining slumps below 4 inches for optimal strength. DON’T accept concrete that appears over-watered or has been in transit too long, as these factors compromise quality and performance.

Forming and Reinforcement Do’s and Don’ts

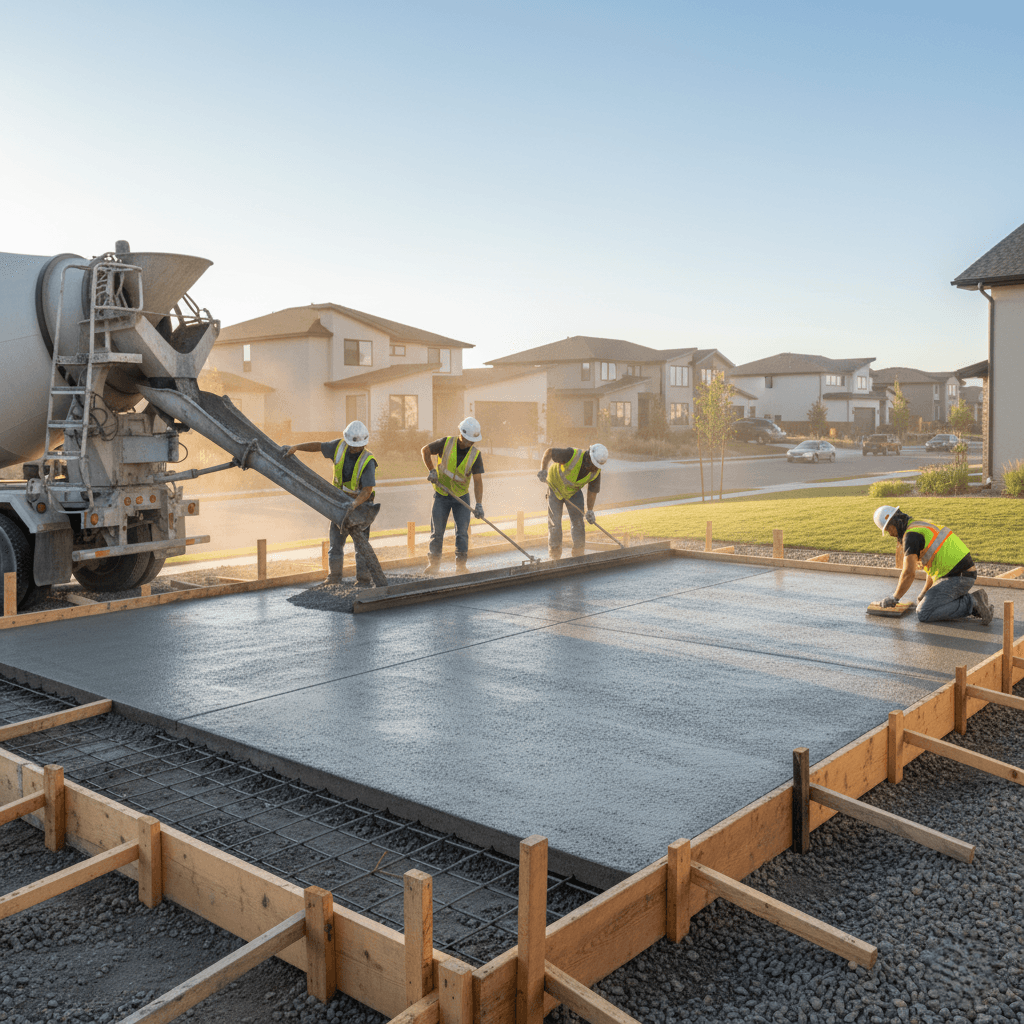

DO construct forms from quality materials and brace them adequately to withstand concrete pressure during placement. Professional installations use precise forming techniques that ensure straight edges and proper thickness throughout the pour. DO install reinforcement, including rebar or wire mesh, according to engineering specifications and local building codes.

DON’T use warped or damaged forming materials that can’t maintain proper alignment during concrete placement. DON’T remove forms prematurely, typically requiring 24-48 hours minimum before form removal, depending on temperature conditions. Premature form removal can cause edge damage and structural weakness.

Placement and Consolidation Do’s and Don’ts

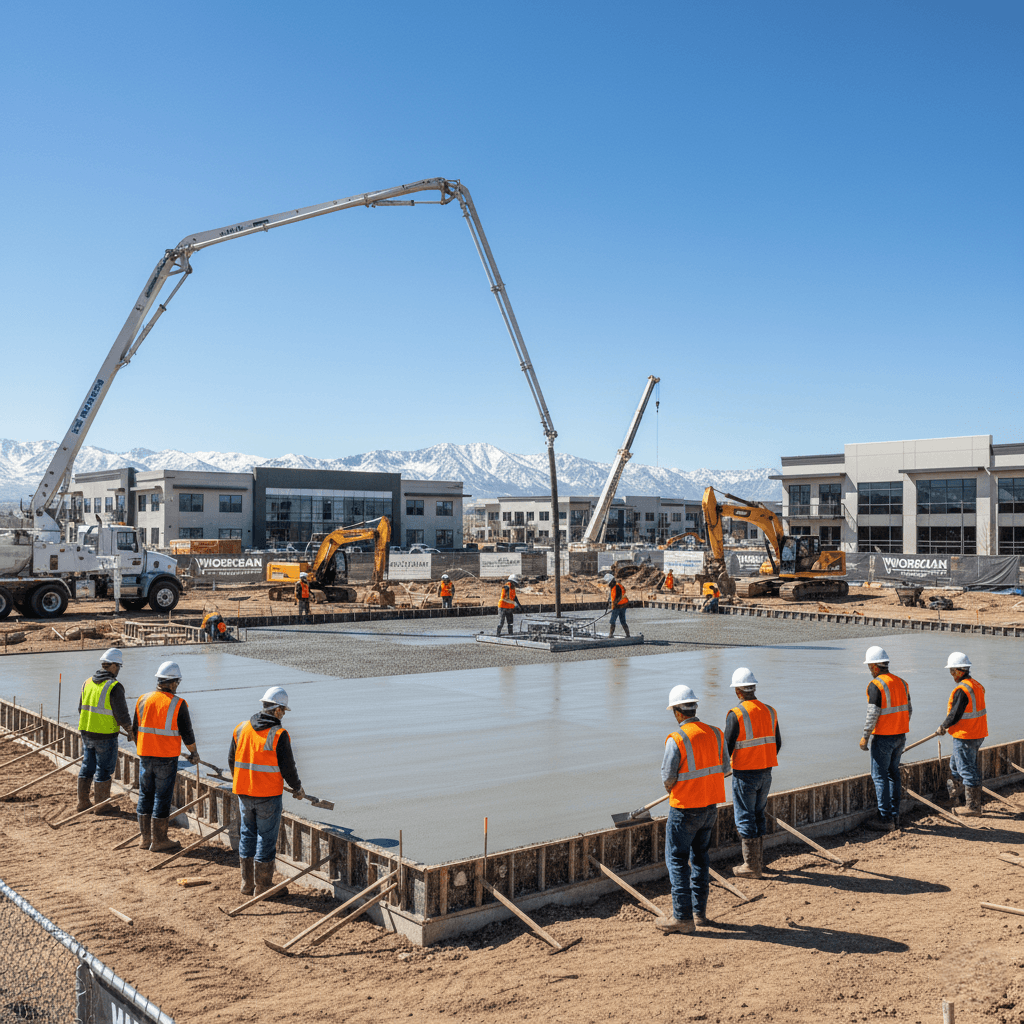

DO pour concrete continuously and work quickly to maintain consistent placement throughout the project. Use proper consolidation techniques, including vibration, to eliminate air voids and ensure complete form filling. DO maintain consistent concrete thickness according to design specifications, typically 4-6 inches for residential applications.

DON’T allow concrete to sit in wheelbarrows or pumps for extended periods, as this can cause segregation and setting problems. DON’T neglect proper consolidation, which can result in honeycombing, weak spots, and surface defects that compromise both appearance and structural integrity.

Professional Placement Techniques

DO start placement at one end and work systematically to avoid cold joints and ensure uniform consistency. DO coordinate crew members to maintain steady progress while maintaining quality control throughout the pour. DON’T attempt large pours without sufficient crew size and equipment to complete the work before the initial set begins.

Finishing Do’s and Don’ts

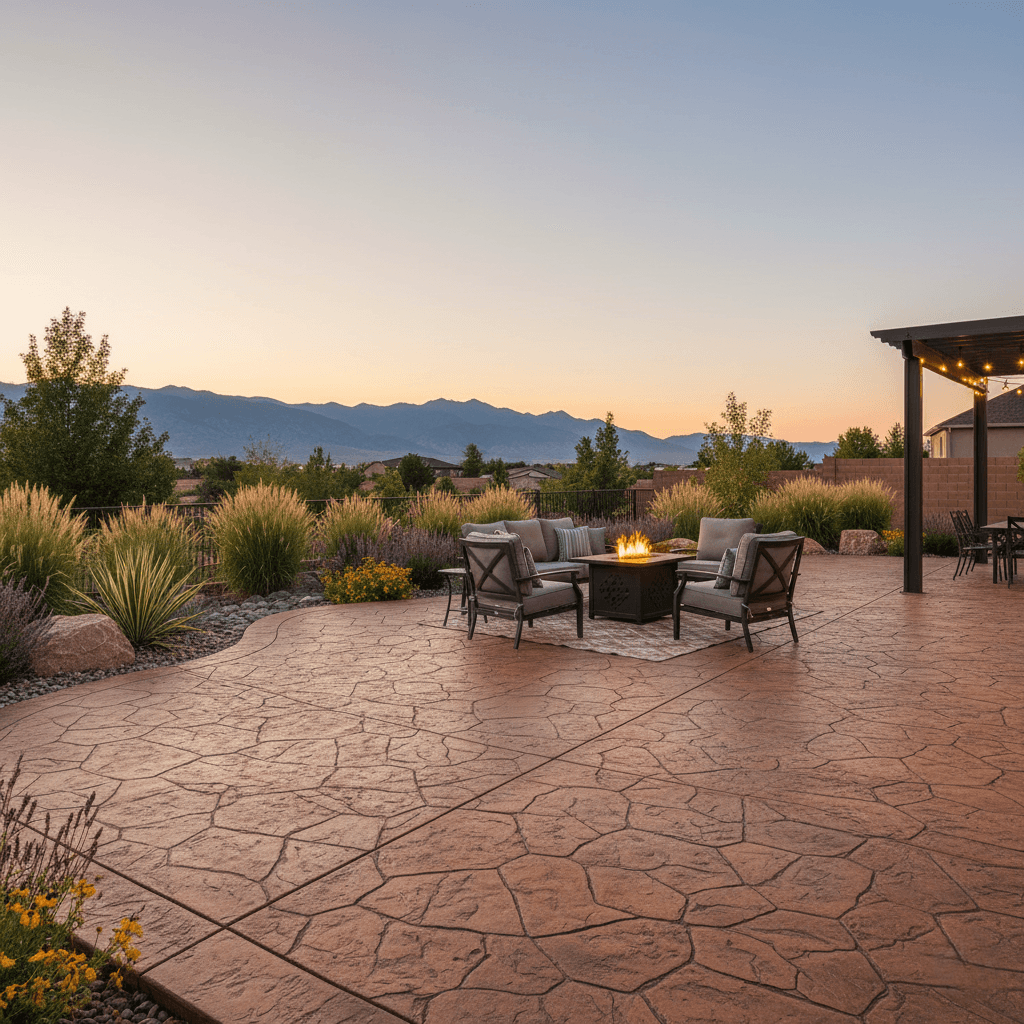

DO wait for surface bleed water to evaporate before beginning finishing operations, as premature finishing can cause surface scaling and dusting. Use appropriate finishing tools, including screeds, floats, and trowels, in proper sequence to achieve the desired surface characteristics. DO create control joints at appropriate intervals to manage cracking from shrinkage.

DON’T over-trowel concrete surfaces, which can bring too much paste to the surface and create weak, dusty finishes. DON’T finish concrete too early while bleed water is still present, as this traps water beneath the surface and causes long-term durability problems.

Curing Do’s and Don’ts

DO implement proper curing procedures immediately after finishing, using methods appropriate for South Jordan’s climate conditions. Maintain concrete moisture and temperature for optimal strength development during the critical first 7-28 days. DO apply curing compounds or use wet curing methods to prevent premature moisture loss.

DON’T allow concrete to dry too quickly, particularly during hot, windy conditions common in South Jordan summers. DON’T subject new concrete to foot traffic or loading before it reaches sufficient strength, typically 7 days for light traffic and 28 days for full loading.

Climate-Specific Curing

DO protect concrete from extreme temperature variations during curing, using insulation blankets in cold weather and shade structures during hot periods. DO extend curing periods during cooler weather when strength development occurs more slowly. DON’T rush the curing process, as proper hydration is essential for achieving design strength and durability.

Safety Do’s and Don’ts

DO wear appropriate personal protective equipment, including gloves, eye protection, and suitable clothing, when handling concrete. The alkaline nature of concrete can cause skin burns and eye irritation with prolonged contact. DO have emergency eyewash facilities available during concrete pours.

DON’T handle fresh concrete with bare hands or allow concrete to contact exposed skin for extended periods. DON’T ignore safety protocols for equipment operation, particularly when using concrete pumps, vibrators, and other power tools during placement operations.

Quality Assurance Do’s and Don’ts

DO document concrete pours with delivery tickets, temperature records, and progress photographs for quality control and warranty purposes. Professional contractors maintain detailed records that help identify any issues and provide documentation for future reference. DO perform strength testing when required by building codes or project specifications.

DON’T skip inspection opportunities during critical phases, including reinforcement placement, concrete delivery, and finishing operations. DON’T proceed with subsequent construction phases until concrete has achieved sufficient strength for safe loading and construction traffic.

Professional vs. DIY Considerations

DO realistically assess project complexity and personal skill levels before attempting DIY concrete pours. Simple projects like small walkways may be suitable for experienced DIYers, while driveways, foundations, and decorative installations typically require professional expertise. DO consult with professionals for guidance on complex projects, even if planning DIY execution.

DON’T underestimate the physical demands and time constraints of concrete pouring, which requires continuous work once placement begins. DON’T attempt large or complex pours without adequate crew size, equipment, and experience to ensure quality results and proper finishing within available working time.

South Jordan Concrete Pros follows these essential do’s and don’ts for every concrete pouring project throughout the South Jordan area, ensuring superior results through proven techniques and local expertise. Our experienced team understands Utah’s specific challenges and implements best practices that deliver lasting performance, structural integrity, and aesthetic appeal for all types of residential and commercial concrete installations.