Innovative Concrete Repair Techniques in South Jordan

Concrete Repair South Jordan

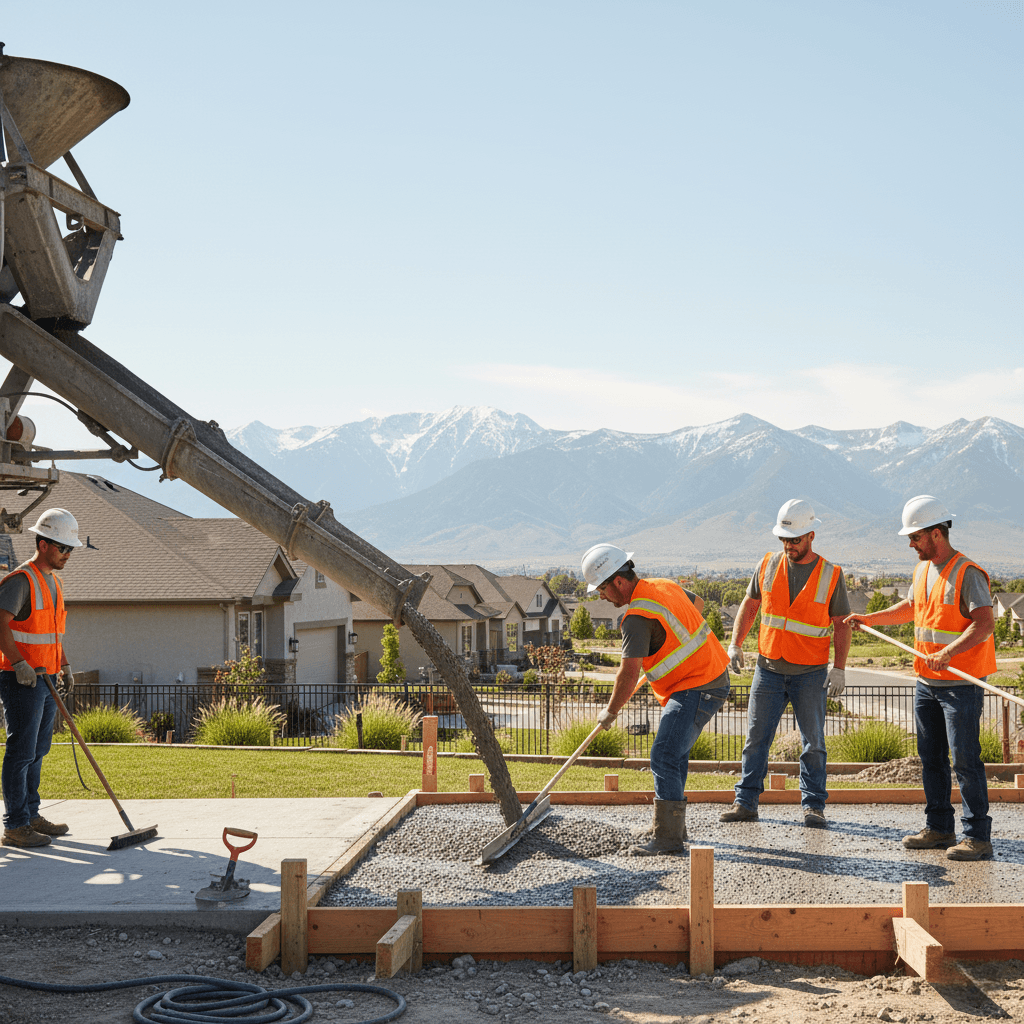

Modern concrete repair techniques revolutionize how South Jordan contractors address structural damage through advanced materials and cutting-edge application methods. These innovative approaches offer superior durability, faster installation times, and enhanced performance compared to traditional repair strategies. Professional contractors increasingly adopt emerging technologies like self-healing concrete, carbon fiber reinforcement, and nanotechnology-enhanced materials for lasting solutions. Moreover, South Jordan’s challenging climate conditions and diverse soil types demand repair methods that adapt to local environmental stresses. Understanding these advanced techniques helps property owners make informed decisions about concrete repair investments that provide maximum value and longevity.

Self-Healing Concrete Technology

Revolutionary self-healing concrete incorporates specialized bacteria or encapsulated healing agents that automatically repair cracks when exposed to moisture. This biotechnology mimics natural healing processes, with bacteria producing limestone to fill crack voids and restore structural integrity. The healing agents remain dormant until cracks develop and water infiltration activates the repair mechanism. This innovative approach significantly extends concrete lifespan while reducing maintenance requirements for South Jordan properties subject to freeze-thaw cycles and soil movement.

Applications and Benefits

Self-healing concrete proves particularly valuable for critical infrastructure like bridges, tunnels, and foundation systems, where access for traditional repairs is difficult or costly. The technology can double surface lifespan in harsh Utah climate conditions, making it ideal for driveways, sidewalks, and exterior concrete exposed to de-icing chemicals. Current implementations show promising results in reducing overall maintenance costs by 50-70% over traditional concrete systems.

Advanced Carbon Fiber Reinforcement

Carbon fiber repair systems provide structural reinforcement that’s 10 times stronger than steel while remaining lightweight and corrosion-resistant. Modern carbon fiber applications include crack stitching using proprietary ReGrid technology that creates bonds significantly stronger than traditional repair methods. These systems install quickly through single saw cuts filled with structural epoxy, reducing labor costs while providing permanent crack stabilization.

Ultra-High Pressure Polyurethane Injection

Advanced polyurethane injection systems utilize ultra-low viscosity formulations that penetrate hairline cracks as narrow as 0.002 inches. These expanding foams increase volume by 15-30 times their liquid state, ensuring complete void filling throughout crack networks. Modern injection systems work effectively in both wet and dry conditions, making them ideal for South Jordan’s variable moisture conditions and basement waterproofing applications.

Technological Improvements

Current polyurethane technologies feature enhanced bonding properties, faster cure times, and improved flexibility to accommodate ongoing structural movement. Professional concrete contractors utilize high-pressure injection equipment with drill-in-place mechanical packers that allow precise material placement into the tightest crack formations. These systems effectively repair actively leaking cracks without requiring dry conditions or extensive surface preparation.

Nanotechnology-Enhanced Repair Materials

Nanotechnology applications in concrete repair involve nanoparticle additives that enhance bond strength, reduce permeability, and improve overall performance characteristics. These microscopic materials fill voids at the molecular level, creating denser, more durable repair zones. Nano-enhanced epoxies and sealers provide superior protection against water infiltration and chemical exposure common in Utah’s challenging environmental conditions.

3D Printing Applications for Concrete Repair

Emerging 3D printing technologies enable custom repair components and complex geometries previously impossible with traditional methods. Specialized concrete printing materials allow on-site fabrication of repair elements tailored to specific structural requirements. This technology reduces waste, speeds construction timelines, and enables creative solutions for unique architectural challenges throughout South Jordan’s diverse building stock.

Smart Monitoring and Diagnostic Systems

Innovative concrete repair increasingly incorporates smart monitoring technologies that track structural performance and predict maintenance needs. Embedded sensors monitor stress, moisture, and movement patterns to provide early warning of developing problems. These systems enable proactive maintenance scheduling that prevents minor issues from developing into major structural concerns, particularly valuable for South Jordan’s expansive clay soil conditions.

Real-Time Assessment Capabilities

Advanced diagnostic equipment includes ground-penetrating radar, ultrasonic testing, and thermal imaging that reveal hidden damage patterns without destructive testing. These non-invasive assessment methods allow contractors to develop targeted repair strategies that address root causes rather than surface symptoms. Real-time monitoring capabilities help optimize repair timing and material selection for maximum effectiveness.

Ultra-High Performance Concrete (UHPC)

UHPC repair applications utilize advanced formulations with steel fibers and supplementary cementitious materials to achieve exceptional strength and durability. These materials provide superior resistance to freeze-thaw damage, chemical exposure, and abrasion while maintaining workability for precision repairs. UHPC proves particularly effective for high-stress applications like bridge repairs and industrial flooring, where traditional concrete fails.

Bio-Based and Sustainable Repair Materials

Innovative repair techniques increasingly incorporate bio-based materials and recycled components to reduce environmental impact while maintaining performance standards. These sustainable approaches include fly ash concrete, recycled aggregate systems, and bio-concrete formulations that sequester carbon during curing. South Jordan contractors can offer environmentally responsible repair solutions that align with modern sustainability goals.

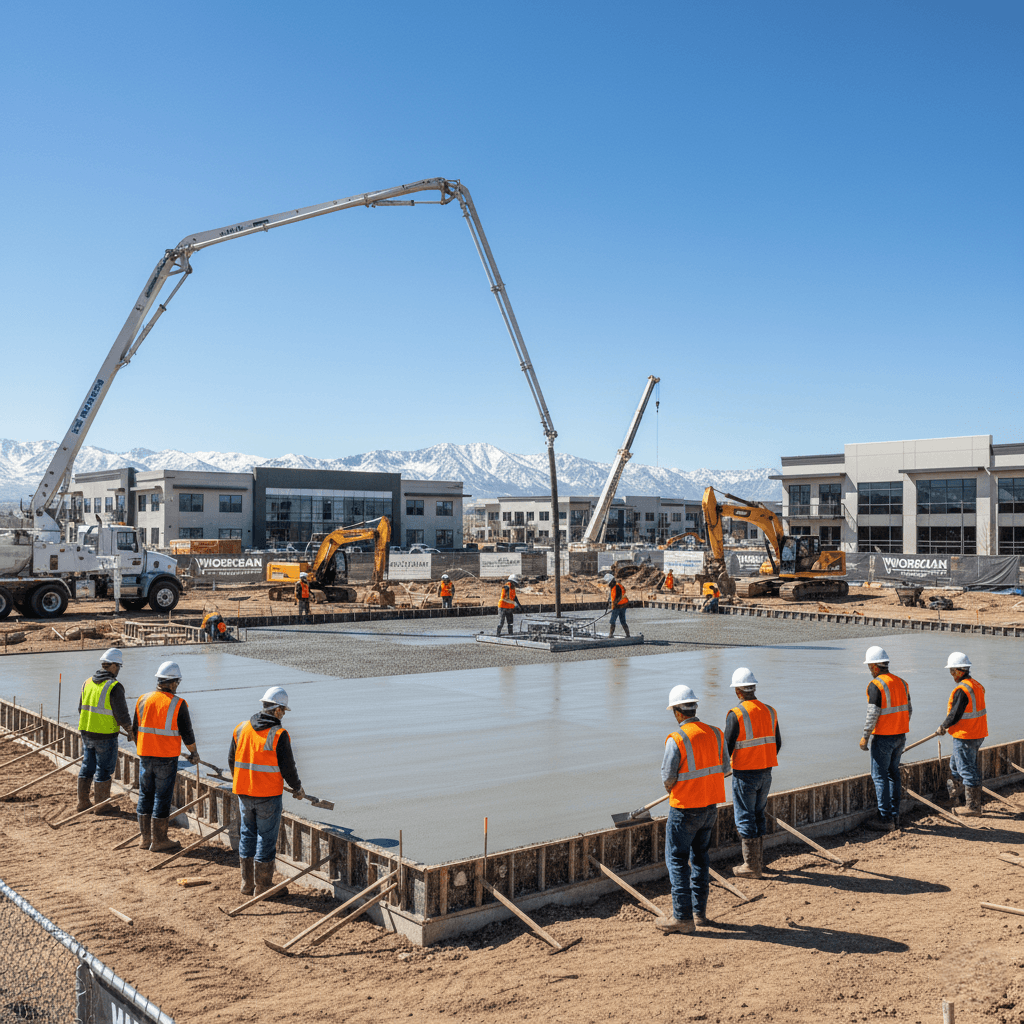

Robotic and Automated Application Systems

Advanced application methods utilize robotic systems and automated equipment for consistent, high-quality repairs in challenging environments. Drone-based spraying systems enable repairs in difficult-to-access locations while maintaining precision and safety. These technologies reduce labor requirements and improve quality control, particularly valuable for large-scale projects or hazardous repair environments.

Flexible and Bendable Concrete Technologies

Engineered cementitious composites (ECC) create bendable concrete with exceptional ductility that accommodates structural movement without cracking. This innovative material can deform 300-500 times more than traditional concrete before failure, making it ideal for seismic areas and structures subject to thermal cycling. Bendable concrete applications include overlay repairs and critical infrastructure, where crack prevention is paramount.

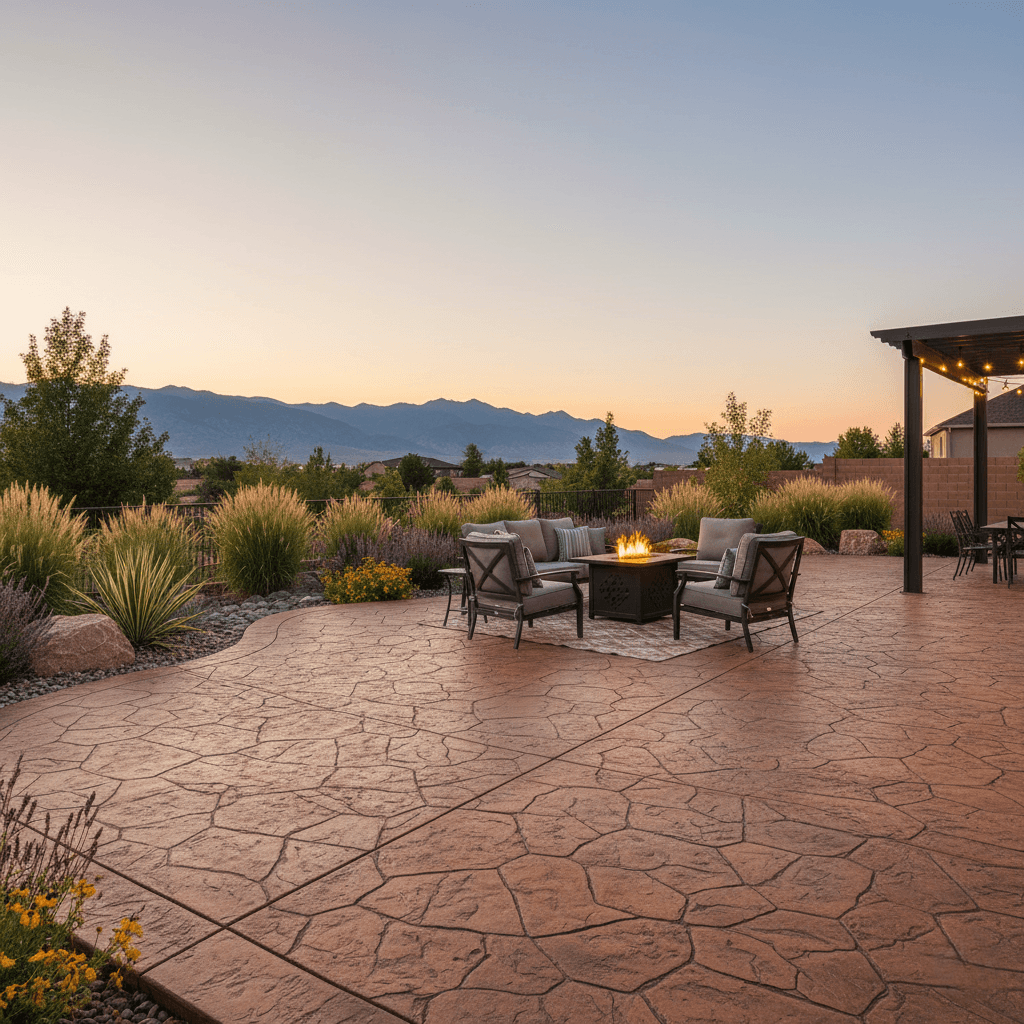

Advanced Surface Treatments and Coatings

Modern protective coatings incorporate nanotechnology, polyurea systems, and multi-layer applications that provide comprehensive protection against environmental damage. These advanced treatments offer superior adhesion, chemical resistance, and durability compared to traditional sealers. Professional applications can extend concrete surface life by 200-300% while maintaining aesthetic appeal and functionality.

Integration with Building Information Modeling (BIM)

Innovative repair projects increasingly utilize BIM technology for planning, visualization, and execution of complex restoration work. Digital modeling allows precise material quantification, scheduling optimization, and quality control throughout the repair process. This technology proves particularly valuable for historic preservation projects and complex structural repairs requiring detailed coordination.

Quality Assurance and Performance Monitoring

Advanced concrete repair techniques incorporate comprehensive quality assurance protocols, including real-time testing, performance monitoring, and long-term assessment programs. Modern testing equipment provides immediate feedback on repair effectiveness, curing progress, and structural performance. These quality control measures ensure repair longevity and provide documentation for warranty protection and future maintenance planning.

South Jordan Concrete Pros stays at the forefront of innovative concrete repair technologies, utilizing advanced materials and cutting-edge application methods to deliver superior results throughout the South Jordan area. Our commitment to continuous improvement and technology adoption ensures your concrete repair projects benefit from the latest innovations while providing exceptional durability, performance, and value for years to come.